- Consumables

- Formwork

Concrete columns are a crucial design element in the construction of buildings such as multi-storey homes, industrial buildings, shopping centres, and parking garages. Because of the force a load-bearing concrete column may need to withstand, column forms are often constructed around steel reinforcement rods.

How is a Concrete Column Made?

All concrete columns must rest on a suitable foundation or footing. The engineer responsible for the building’s design can calculate the required thickness of the foundation according to the weight of the column, and the load it must sustain. When constructing the footing, metal reinforcing starter bars are embedded in the foundation so that they extend out of its surface. These bars provide a place to attach steel bars that can reinforce the concrete pillar itself.

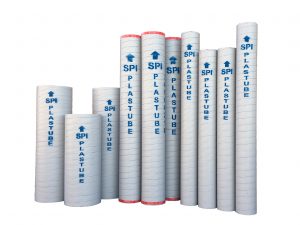

Engineers also need to calculate the required diameter for the column to sustain the load it will be under safely once construction is complete. There are no standard lengths or diameters to SPI Plastube, which means we can make our column forms to the customer’s exact requirements in any diameter between 250mm and 2000mm and to the required length. With either light or heavy-duty columns in mind, Plastube column forms are available in two thicknesses of PVC profile depending on the diameter and height of concrete pour.

Once the formwork is secured in place around the steel reinforcement, the construction crew can mix and pour concrete into the formwork. When the concrete is sufficiently hardened, we then remove the formwork. SPI Plastube’s formwork design makes it easy to strip the column forms away from the hardened column.

Aesthetics are Incorporated in the Design with SPI Plastube Column Forms

When pouring a concrete column using a Plastube column form, the column can be supplied with a standard structural finish, or if the columns are to be exposed, you might prefer an architectural finish. A structural finish shows a spiral line on the finished column, while columns with an architectural finish have one or more vertical lines along the length of the column with a smooth finish in between. Depending on the diameter, columns are lined with rigid plastic sheets to form the vertical lines.

Advantages of SPI Plastube Column Forms

Although SPI Plastube column forms are lightweight and easy to handle, they are weather durable and have a robust construction. Plastube column forms have a Class 2 finish and are made in Australia from locally sourced materials. Our column forms are easy to install, pour and strip, and are the most cost-effective and versatile column formwork on the market.

Contact SPI for Column Forms

SPI Equip are located in Sydney & Brisbane and have a strong reputation for providing innovative solutions to construction and formwork companies all over Australia. We pride ourselves on our construction experience to provide sound engineering advice to our customers and can collaborate with you to find a positive, sustainable solution for your construction challenges. Contact SPI today for a quote for all your formwork and construction equipment at competitive prices.